Research Progress

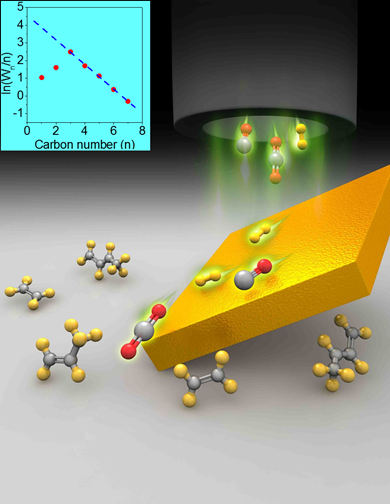

Lower olefins refer to ethylene, propylene and butylene, which are vital building block in the chemical industry. They are fundamental chemicals of the greatest consumption among the organic chemicals all over the world. Large amount of chemical products such as packing materials, cosmetics, synthetic rubber, coatings are the derivatives of lower olefins. In traditional petrochemical industry, lower olefins are mainly derived from oil-based feedstocks. With the rapid depletion of the limited petroleum, there is an urgent need for processes that can produce lower olefins from alternative feedstocks. The syngas, which is a promising alternative feedstock as it can be obtained from reforming of natural gas, gasification of coal or biomass, can be transformed into lower olefins through Fischer-Tropsch to olefins (FTO) process as an attractive alternative non-petroleum-based production route due to its process simplicity and low energy consumption. The primary aims of FTO are to maximize lower olefins selectivity while reduce methane production with high stability. However, the hydrocarbons obtained with the FTO process typically follow the so-called Anderson–Schulz–Flory distribution, which is characterized by a maximum C2-4 hydrocarbon fraction of about 56.7% and an undesired methane fraction of about 29.2%. It is necessary to develop new FTO catalyst which deviate from ASF distribution at mild reaction conditions. Metallic cobalt is the active phase with high FT activity for production of long-chain paraffin. Cobalt carbide is always considered as one of the main deactivation reasons for Co-based FT reaction and produces a large amount of unwanted methane. However, CAS Key Laboratory of Low-Carbon Conversion Science and Engineering Shanghai Advanced Research Institute, Chinese Academy of Sciences, now report that, under mild reaction conditions (250 oC, 1~5 bar), Co2C nanoprisms catalyse the syngas conversion with high selectivity for the production of lower olefins (60.8 C%), while generating little methane (about 5.0 C%), with the ratio of olefin/paraffin amongst the C2-4 products being as high as 30. The product distribution deviates markedly from the classical ASF distribution with the highest selectivity to propylene. Based on study of structure-performance relationship and DFT calculations, a strong facet effect was demonstrated for Co2C nanoparticles during syngas conversion. Specifically, the {101} and {020} facets of Co2C are beneficial for the production of olefins and inhibit the formation of methane (Figure 1).

The above research result is recently published at Nature. The high activity, selectivity and stability at mild reaction conditions suggest promising potential industrial application. As Prof. Michael Claeys (one of the reviewers) has said in the NEWS & VIEWS at Nature, “their potential impact cannot be overestimated: they might open up pathways for the development of greatly improved systems for producing valuable chemicals from a variety of carbon sources” and “this is a groundbreaking contribution that further unlocks the immense potential of the Fischer–Tropsch process for producing chemicals. Zhong et al. have thrown open the reaction’s treasure chest, and added fresh momentum to research into methods for making olefins from synthesis gas”.

This work has been supported by the Natural Science Foundation of China, the Shanghai Municipal Science and Technology Commission, Shanxi Lu’an Coal Corporation Limited, the Ministry of Science and Technology of China and the Chinese Academy of Sciences.

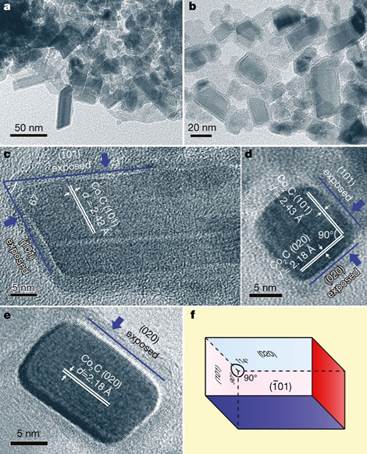

Figure 1 TEM images of the CoMn catalysts after reaching steady state. (a, b) Low-resolution TEM images. (c-e) High-resolution images of Co2C nanoprisms with exposed facets of (101), (-101) and (020). d, distance (length) of the lattice fringes. (f) The Co2C nanoprism has a parallelepiped shape, with four rectangular faces and two rhomboid faces.

Figure 2. Cobalt carbide nanoprisms for direct production oflower olefins from syngas (Nature, 2016, 538, 84)