Microreactor exhibits great potential for intensified synthesis of advanced materials and chemicals in continuous flow mode, for its various advantages such as excellent heat and mass transfer efficiency, high controllability, easy scale-up, etc. Among numerous flow patterns, gas-liquid Taylor flow represents the characteristics of wide operation window, low axial back mixing and good radial mixing, thus, has been proven as an ideal flow regime to enhance chemical reactions. However, the method to precisely control the Taylor flow pattern is still lacking.

Motivated by such a challenge, a research team led by Prof. TANG Zhiyong and Associate Prof. Zhang Jie at Shanghai Advanced Research Institute (SARI), Chinese Academy of Sciences, reported a novel approach of adding pulsation field to precisely regulate the gas-liquid Taylor Flow. The research results were published in Chemical Engineering Journal entitled “Regulation of Gas-Liquid Taylor Flow by Pulsating Gas Intake in Micro-channel” .

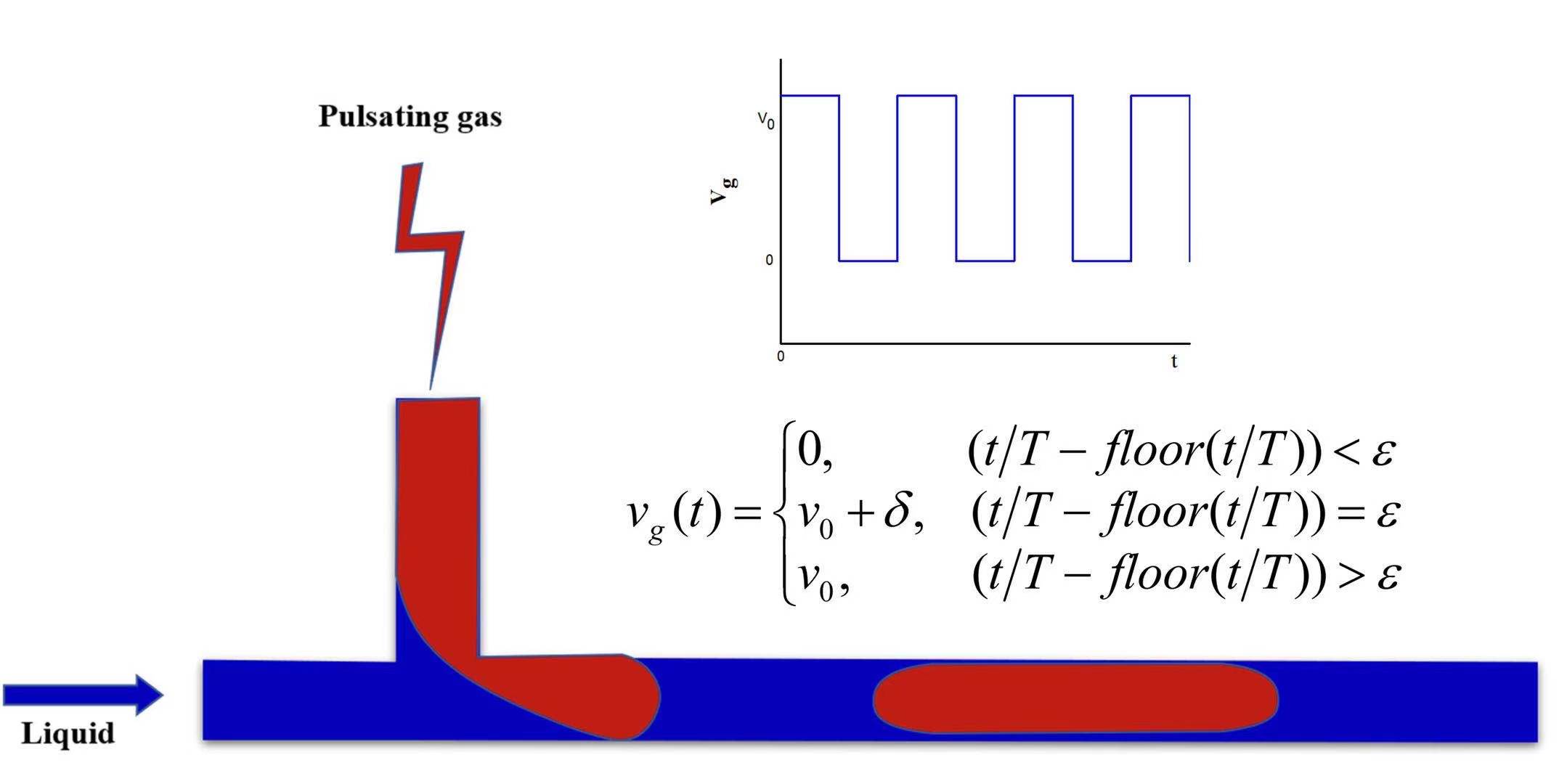

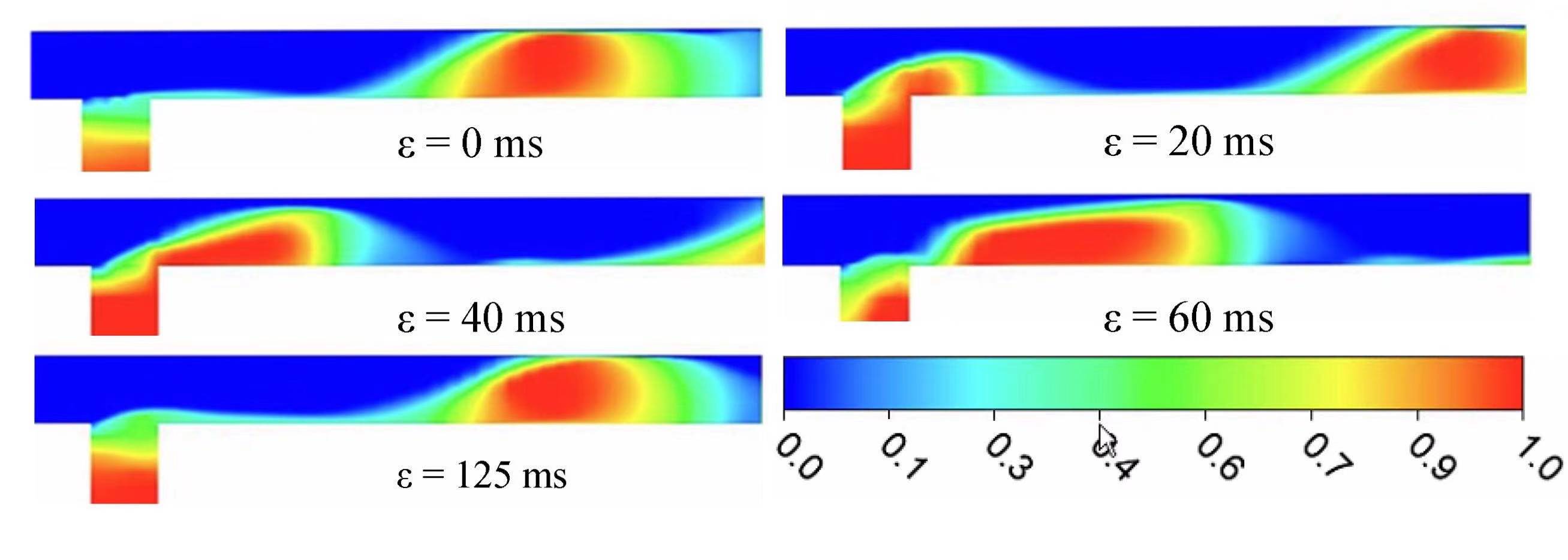

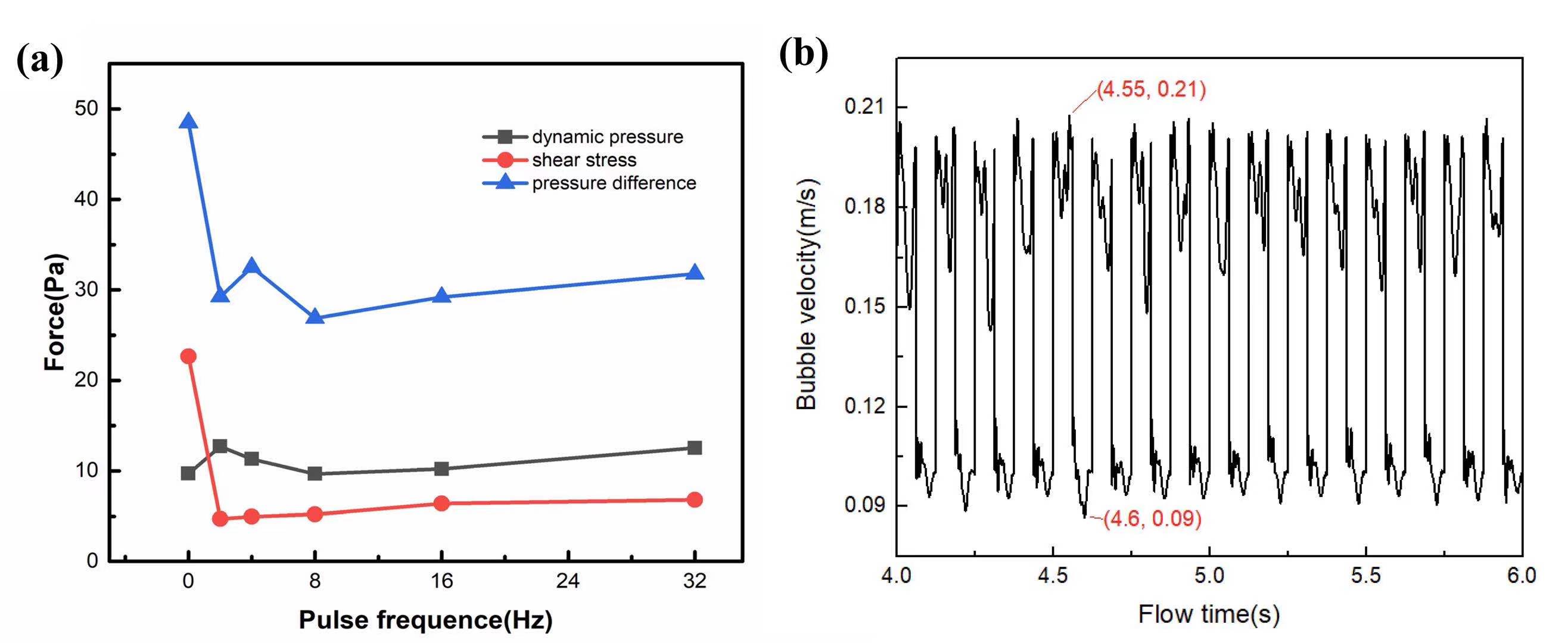

In this work, the research team used a simple valve arrangement to introduce the pulsation filed, thus producing periodic acceleration and deceleration motion of liquid slugs. By combing visual flow experiments with computational fluid dynamics (CFD) simulation, the temporal-spatial migration of the Taylor flow pattern under pulsating gas intake conditions was investigated. A high-speed camera is used to track the trajectory of gas-liquid interface by the Lagrangian method, while the numerical simulation is used to acquire the flow field distribution at different moments using the Euler method. Meanwhile, the involved forces during bubble formation and the characteristics of bubble length and velocity under pulsation were analyzed in detail.

By studying the temporal-spatial migration of the pattern, scientists found that the pulsation can increase the power of inertial force on the Taylor flow pattern. Moreover, the pattern can be destroyed when the pulsation energy exceeds a certain value.

This work provides a new route to regulate precisely the gas-liquid Taylor flow, and will contribute to future applications of this technique to intensify various gas-liquid reactions in continuous flow.

This work was supported by the Youth Innovation Promotion Association of Chinese Academy of Sciences, the STS Program of Chinese Academy of Sciences and Frontier Scientific Research Project funded by Shell.

Figure 1. Regulation of Gas-Liquid Taylor Flow by Pulsating Gas Intake in Micro-channel (Image by SARI)

Figure 2 Space-time distribution of gas fraction in bubble formation process (Image by SARI)

Figure 3 (a) Forces versus pulse frequency f at the T-junction, (b) Bubble velocities at downstream(Image by SARI)