Photocatalytic reactions, which allow unlocking some chemical transformations under mild conditions that are unavailable to conventional ground-state pathways, can save energy consumption and improve intrinsic safety of the processes. As a sustainable and low-carbon technology, it has high potential to contribute to the national commitment of carbon peak and carbon neutrality. Continuous flow chemistry can, to a large extent, migrate the “light limitation” problem in traditional batch protocols, and the use of heterogeneous photocatalysis can overcome the disadvantages of difficult catalyst recovery in homogeneous systems. However, effective handling of the solid photocatalysis in continuous flow still remains very challenging.

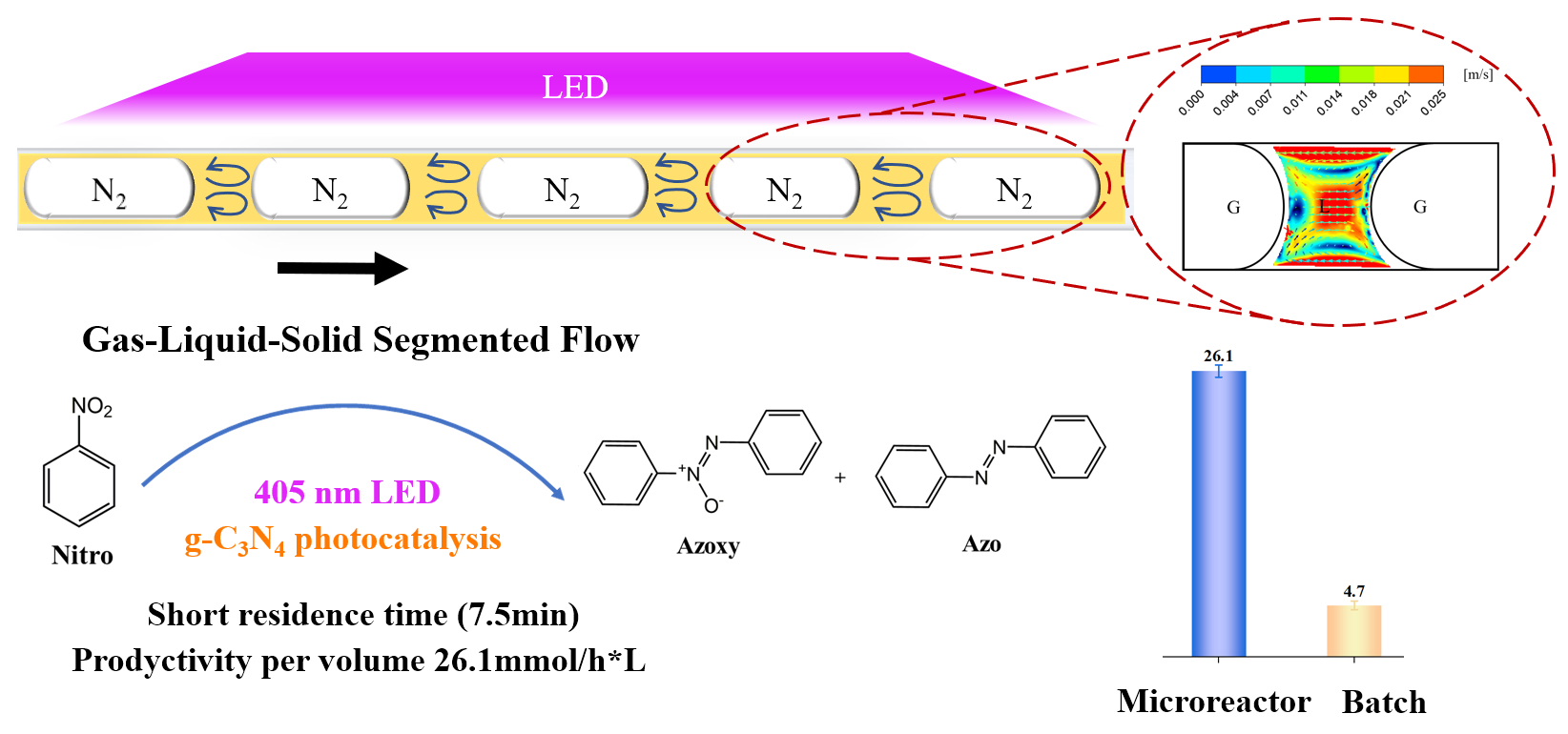

Motivated by such a challenge, a research team led by Prof. TANG Zhiyong and Associate Prof. Zhang Jie at Shanghai Advanced Research Institute (SARI), Chinese Academy of Sciences, reported a novel approach of gas-liquid-solid segmented flow, which enabled utilizing the solid photocatalysis in continuous flow without clogging. Owning to the inner recirculation in liquid segments and the formed thin film, this method ensures the effective suspension of solid catalysts in flow, resulting in enhanced mass transfer and irradiation. The research results were published in Chemical Engineering Journal entitled “Tuning the Gas-Liquid-Solid Segmented Flow for Enhanced Heterogeneous Photosynthesis of Azo- Compounds” .

Azobenzene and azoxybenzene are important precursors in pigment industry, electronic industry and pharmaceutical industry. In this work, the selective synthesis of azo- compounds from nitrobenzene by graphitic carbon nitride (g-C3N4) photocatalysis was selected as model photocatalytic reaction. By combing the visual flow experiments, the model reaction under gas-liquid-solid segmented flow was investigated thoroughly. Meanwhile, the effects of flow behavior on the photoreaction performance were quantified.

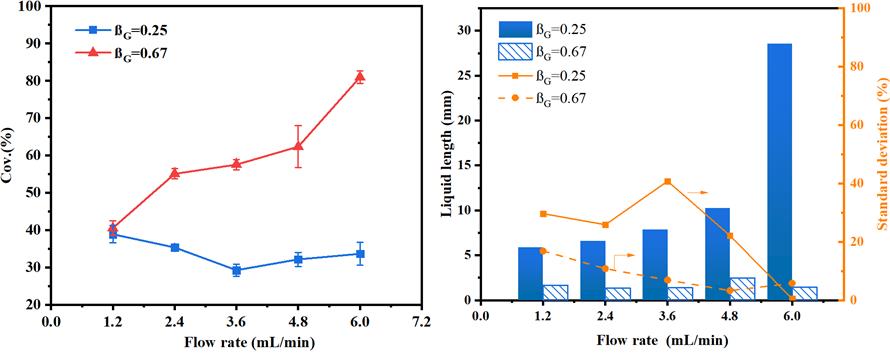

Scientists found that the continuous flow could greatly shorten the reaction time. The photocatalytic reaction performance was very sensitive to the gas-liquid-solid segmented flow conditions, which needed to be carefully tuned. It was identified that the increasing inert gas fraction resulted in more stable segmented flow with shorter liquid segments and thinker liquid film. The maximum productivity per volume of the continuous photo-microreactor reached 26.1 mmol/h*L. Benefiting from the advantage of “numbering-up”, this value was more than 500 times that of the batch reactor (80 L) reported in the open literature. These results demonstrated great potential of gas-liquid-solid segmented flow in the field of heterogeneous photocatalysis.

This work provides a new route to utilize the heterogenous catalysis in continuous flow, which can be applied as a universal method to intensify the synthesis of functional materials, fine chemicals and active pharmaceutical ingredients (APIs), thereby promoting the transformation from conventional batch processes to green, safe and efficient continuous flow processes.

This work was supported by the Youth Innovation Promotion Association of Chinese Academy of Sciences, the STS Program of Chinese Academy of Sciences, and Frontier Scientific Research Project funded by Shell.

Figure 1. Heterogeneous photosynthesis of azo- compounds in gas-liquid-solid segmented flow (Image by SARI)

Figure 2. Comparison of the photocatalytic performance between (a) the batch reactor and (b) the continuous flow microreactor (Image by SARI)

Figure 3. Effects of total flow rate on the nitrobenzene conversion and the liquid segment length in the gas-liquid-solid segmented flow (Image by SARI)

Contact: TANG Zhiyong

Shanghai Advanced Research Institute, Chinese Academy of Sciences

Email: tangzy@sari.ac.cn