Research Progress

Novel Approach to Fabricating Gadolinium Oxide Structure Neutron Absorber by 3D Printing

date:

2022-08-29

The exceptional proprieties of gadolinium oxide (Gd2O3) enable wide applications as sensitized fluorescent material, optical additive, and especially neutron absorber material for nuclear industry or nuclear medicine. However, due to high melting point (2350 °C) and hardness, it is very difficult to manufacture the custom-designed Gd2O3 with traditional milling, curving, injection molding and the binder sacrifice method.

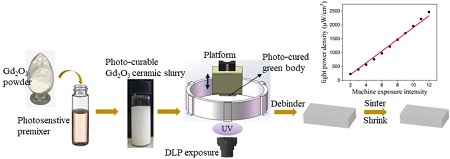

Motivated by such a challenge, a research team at Shanghai Advanced Research Institute proposed a new approach to fabricating the Gd2O3 structure by vat photopolymerization 3D printing.

For successful 3D printing, researchers investigated thoughtfully the whole manufacturing process, including the slurry preparation, photocuring parameters, sintering temperature, and mechanical properties of sintered samples.

After debinding and sintering, the resultant Gd2O3 structures reached a density of 58%, a bending stress of 40 MPa, and a flexural elastic modulus of and 20.219 GPa, revealing the influence of sintering temperature on the relative density, micro structure and flexural elastic modulus.

Finally, a green body with a large size of 10 cm was prepared, shedding light on its practical application in the neutron absorption and shielding.

This work provides a novel strategy to precisely prepare the pure Gd2O3 ceramic with structural flexibility. The developed DLP 3D printing method provides an effective route to meet the personalized needs of Gd2O3 structure in the neutron absorption and shielding.

Schematic illustration of DLP 3D-printing of Gd2O3 structure neuron absorber

(Image by SARI)