Research Progress

Researchers Propose a Novel FTO Route with Ultrahigh Carbon Efficiency

date:

2022-10-12

Olefins are key building blocks to manufacture a wide range of value-added products such as polymers, lubricants, plasticizers, drugs, detergent and cosmetics. Syngas conversion serves as a competitive strategy to produce olefins from nonpetroleum resources. However, the goal to achieve desirable olefins selectivity with limited undesired C1 by-products remains a grand challenge.

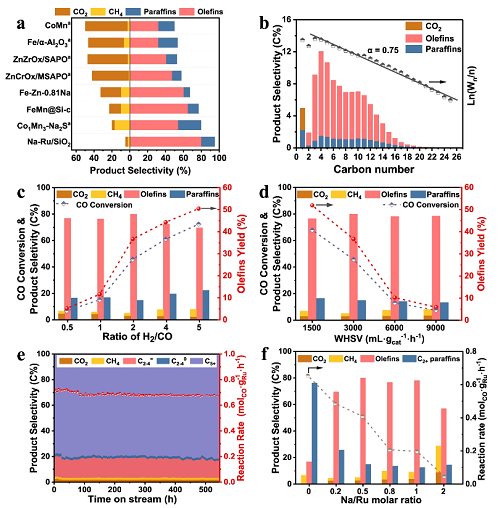

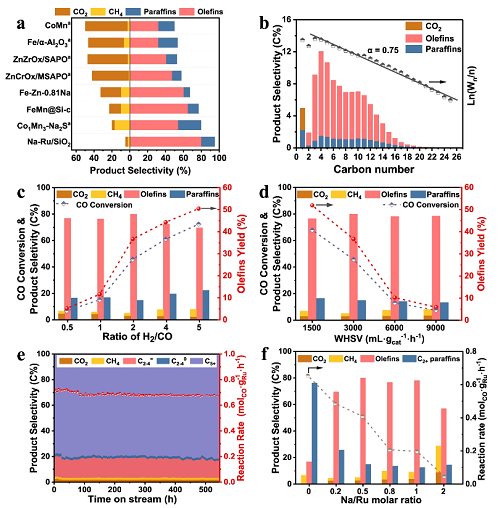

Motivated by such a challenge, a research team led by Prof. ZHONG Liangshu at the Shanghai Advanced Research Institute (SARI) of the Chinese Academy of Sciences reported a non-classical Fischer-Tropsch to olefins (FTO) process featuring high carbon efficiency that realizes 80.1% olefins selectivity with ultralow total selectivity of CH4 and CO2 (<5%) at CO conversion of 45.8%.

The results were published in Nature Communications on 10 October 2022.

The researchers prepared a silica-supported Ru nanoparticles catalyst with sodium (Na) as promoter (denoting as Na-Ru/SiO2), which was highly active for FTO reaction but very inactive for water-gas-shift (WGS) reaction.

With various characterizations and surface probe reaction experiments, the Ru metal is demonstrated to be the active phase, and the Na promoter can suppress the reactivity of chemisorbed H atoms on Ru surface sites while greatly promote the production of olefins, especially for long-chain α-olefins (C5+=), whose fraction in olefins distribution reached up to 74.5%.

No obvious deactivation is observed within 550 hours and the pellet catalyst also exhibits excellent catalytic performance in a pilot-scale reactor, suggesting promising practical applications.

The results of this work demonstrate that the modified-metallic Ru can effectively tune the dominated product distribution from traditional paraffins to value-added olefins. The as-obtained catalytic performance exhibits the highest olefins (especial for C5+=) selectivity and yield together with the lowest fraction of undesired C1 by-products including CH4 and CO2, which outperforms the reported results under all the CO conversion levels in the previous references.

The ultrahigh selectivity and yield of olefins as well as the limited production of C1 by-products enables a considerable carbon efficiency for the current FTO route, and also represents a big step toward the application of Ru-based catalysts for direct production of olefins, especially for long-chain olefins, from syngas.

Catalytic performance for direct syngas conversion to olefins over Na-modified Ru-based catalyst

(Image by SARI)