Research Progress

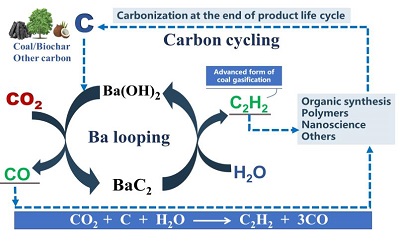

Recently, a research team led by Prof. ZHAO Hong and Prof. JIANG Biao from Shanghai Advanced Research Institute, Chinese Academy of Sciences first proposed a sustainable acetylene and carbon monoxide coproducing process based on BaCO3-BaC2-Ba(OH)2-BaCO3 barium cycle, which can simultaneously realize CO2 capture and acetylene-carbon monoxide co-production at mild dynamic conditions with lower energy consumption and less waste emission.

The results were published in Green Chemistry.

The dynamical behavior investigation suggested that BaC2 can be efficiently solid-phase synthesized at about 1500 ℃ by using carbon and BaCO3 as raw materials without CO2 emission, which is more than 600 ℃ lower than the production temperature of CaC2.

In addition, Ba(OH)2 produced by the gasification of calcium carbide into acetylene is easily recovered and converted into BaCO3 by absorbing CO2, which is then used to synthesize carbide, verifying the coupling process between carbon-to-acetylene and carbon dioxide capture based on Ba loop, reducing the waste of carbide slag.

The results suggested that BaC2 is the more suitable intermediate for carbon-to-acetylene process than CaC2, because of the milder formation temperature, the faster reaction rate, the more convenient barium recover to carbide production.

Featuring low cost, less wastes and high efficiency of co-producing of acetylene and carbon monoxide, this technology is expected to synthesize various of chemicals by using C2H2 and CO as platform chemicals instead of CO and H2 produced by carbon gasification, which provides new ideas about reengineering process of carbon to chemicals.

Schematic of the barium-based carbon-to-acetylene process with the co-production of carbon monoxide (Image by SARI)

Contact: ZHAO Hong

Shanghai Advanced Research Institute, Chinese Academy of Sciences

Email:zhaoh@sari.ac.cn