Research Progress

Novel discovery on Al(III) Doping of ε-Fe2O3 in the Ancient High-iron Black-brown Glaze

date:

2023-10-23

Based on siliceous clay and calcareous wood ash, the world’s first high-fired glazes were made in China, the technology of which was at its zenith by the Song Dynasty (960-1279) including blackware glazes with single-phase, micron-scale ε-Fe2O3 films identified on their surfaces. However, modern synthetic methods are still difficult to synthesize and reproduce the effects on a larger scale without other iron oxide polymorph impurities.

To understand the effect, a research team made up of Prof. WEI Xiangjun from Shanghai Advanced Research Institute (SARI) of the Chinese Academy of Sciences, Dr. LEI Yong and Dr. GUAN Ming from the Palace Museum, and Prof. MA Ding and Dr. GUO Yu from Peking University developed a novel strategy combining nanomaterial science method and theoretical calculation to investigate the hare’s fur glaze of Song Dynasty Jian wares.

The research results were published in Journal of the American Ceramic Society entitled "Uncovering the Mystery of Al(III) Doping of ε-Fe2O3in the Ancient High-iron Black-brown Glaze”.

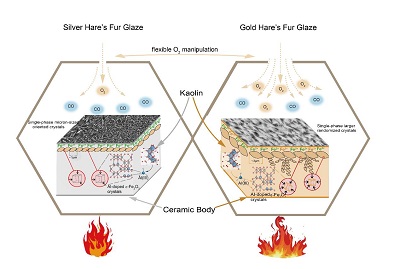

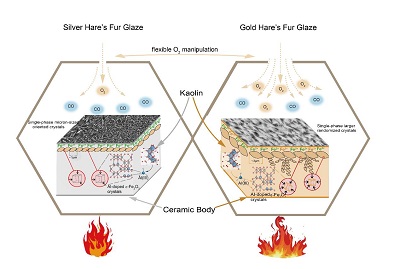

A major breakthrough has been achieved in this work through proving that high-alumina clay introduced Al into the glazes, which doped Al into ε-Fe2O3 lattices and thus stabilized the metastable polymorph based on XRD refinement, TEM-EDS, and theoretical calculation.

Moreover, with SR-based XAS, M?ssbauer spectroscopy and SEM-EBSD, uniform-sized, high-yield and oriented ε-Fe2O3 films and ionic Fe2+ were discovered on a silver hare’s fur glaze, an effect managed by the ancient potters through a subtle control of atmosphere and firing environment.

This work deepens the understanding of high-alumina, high-calcia, high-fired glazes and their subtle firing manipulation technology, which in turn should help advance new approaches to materials synthesis.

The manipulation of firing process of silver and gold hare’s fur glazes. (Image by SARI)