Research Progress

The electrochemical propylene epoxidation reaction (PER) provides a promising route for ecofriendly propylene oxide (PO) production, instantly generating active halogen/oxygen species to alleviate chloride contamination inherent in traditional PER.

However, the complex processes and unsatisfactory PO yield for current electrochemical PER falls short of meeting industrial application requirements.

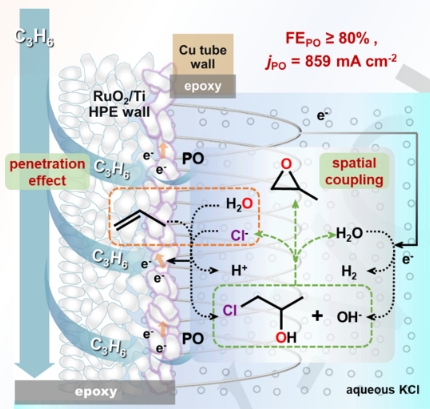

Motivated by such a challenge, a research team led by Profs. CHEN Wei and WEI Wei from the Shanghai Advanced Research Institute (SARI) of the Chinese Academy of Sciences reported a spatial-coupling strategy over RuO2/Ti hollow-fiber penetration electrode (HPE) to facilitate efficient PO production, significantly improving PER performance to ampere level.

The results were published in Angew. Chem. Int. Ed.on Aug 7th, 2024.

The unique penetration effect of HPE forces gaseous propylene dispersion and penetration through the porous HPE wall, leading to greatly boosted PER kinetics from oriented mass transfer and enhanced interface reactions.

Furthermore, the spatial coupling of anodic CP intermediate with cathodic OH− within a membraneless single-chamber reactor establishes a subtle reaction sequence, simplifying the PO production process to one step.

The synergetic combination of the penetration and spatial coupling effects, greatly boosts ampere-level PO production with high specificity, achieving significantly improved PER performance up to ampere level, with PO faradaic efficiency of ≥80% and a maximum PO current density of 859 mA cm−2.

This work exhibits significant potential for economically viable PER applications.

Figure. Schematic illustration of spatial-coupled ampere-level electrochemical propylene epoxidation over RuO2/Ti HPE. (image by SARI)