Research Progress

All-polymer solar cells (APSCs) possess excellent material flexibility, solution processability, and thermal stability, offering great potential for lightweight and large-area printed applications in wearable and stretchable devices. A critical factor in achieving high performance is the optimization of active layer morphology, especially the regulation of crystallization and phase separation of the donor. However, the real-time morphological evolution during post-treatment processes such as solvent vapor annealing (SVA) has remained unclear.

To address this challenge, a research team led by Prof. YANG Chunming at the Shanghai Advanced Research Institute, Chinese Academy of Sciences established an in situ grazing-incidence X-ray scattering platform for organic solar cells at SSRF beamlines BL16B1 and BL10U1.

By combining synchrotron-based grazing-incidence wide-angle X-ray scattering (GIWAXS), in situ ultraviolet-visible (UV–vis) absorption spectroscopy and grazing-incidence small-angle X-ray scattering (GISAXS), they tracked in real time the dynamic morphological changes of blade-coated PM6:PY-IT all-polymer active layers during SVA treatment.

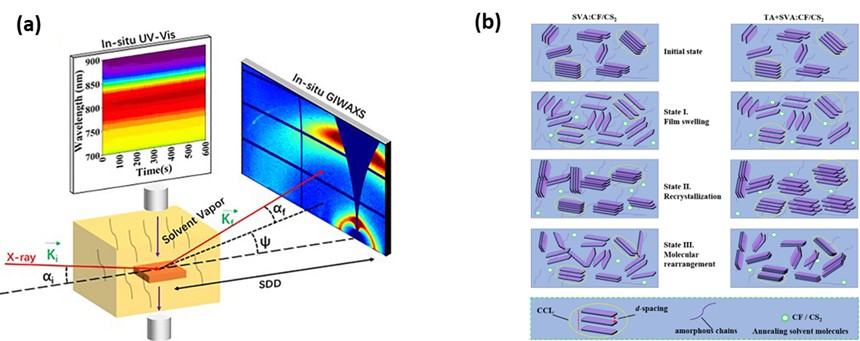

This study, for the first time, revealed a three-stage mechanism (swelling-recrystallization-rearrangement), by which SVA regulates the morphology of all-polymer blended films and its correlation with device performance (Figure 1).

The related results were published in Advanced Science recently.

Figure 1. (a) Schematic diagram of simultaneous in situ GIWAXS and in situ UV–vis measurements during SVA of blade-coated all-polymer solar cells,

(b) Illustration of microscopic morphology evolution under different solvent vapors.

In situ UV–vis spectroscopy revealed that carbon disulfide (CS2) vapor—a nonpolar solvent with high saturated vapor pressure and low solubility, induced a redshift in the PY-IT absorption peak. Conversely, chloroform (CF), a polar solvent with low saturated vapor pressure and high solubility, triggered a blueshift.

This indicates that polar solvents exert a more pronounced effect on the polymer acceptor (PY-IT), driving conformational changes (blueshift) that result in a denser hole transport layer and enhanced hole transport efficiency.

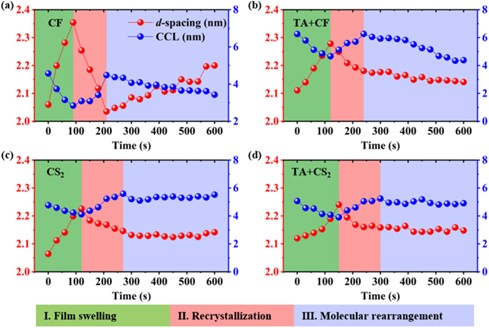

In situ GIWAXS analysis further confirmed three characteristic stages in the SVA process includes: solvent swelling, recrystallization, and molecular rearrangement. An appropriate SVA duration helps stabilize the crystalline structure, as evidenced by reduced lattice spacing, increased charge carrier mobility, and optimized phase separation dimensions, ultimately improving the power conversion efficiency (PCE) of the device. However, prolonged SVA can lead to re-swelling during molecular rearrangement, which is detrimental to performance.

Pretreatment via thermal annealing (TA) effectively suppresses this unfavorable expansion (Figure 2). GISAXS measurements further investigated nanoscale phase separation behavior. Films subjected with combined TA and SVA of CF exhibited optimal morphology, characterized by the maximum donor coherence length (ξ), the largest acceptor aggregate radius (2Rg), and the greatest acceptor coherence length (η).

The TA pretreatment induced increase in PY-IT aggregate size is key to achieving balanced crystallinity and ideal phase separation, promoting efficient charge separation and transport. This work clarified a critical mechanism: SVA with polar solvents primarily optimizes molecular packing, while SVA with nonpolar solvents tends to enhance phase separation.

These insights provide a clear strategy for synergistic process-material optimization—such as combining TA with polar solvent SVA—to fabricate high-performance blade-coated devices.Furthermore, the findings lay an important foundation for future exploration of multi-solvent synergistic annealing, precise control of dynamic processes, and the development of environmentally friendly green processing, thereby accelerating the industrialization of large-area flexible APSCs.

Figure 2. Evolution of d-spacing and CCL evolution of (OOP)100 peak for blade coated PM6: PY-IT blend films with a) CF, b)TA+ CF, c) CS2, and d) TA+ CS2.