Research Progress

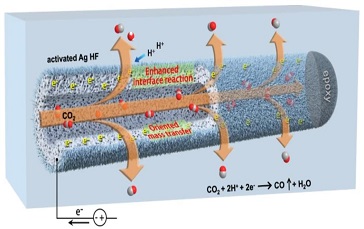

Novel Silver Hollow Fiber Boosts CO2 Electroreduction

A research team led by Prof. WEI Wei and CHEN Wei reported a hierarchical micro/nanostructured silver hollow fiber electrode that reduces CO2 to CO with CO2 conversions exceeding 54% at a high space velocity of 31000 mL?gcat-1?h-1 under ambient conditions, maintaining stable large current densities (~1.26 A?cm-2) and high CO faradaic efficiencies (~93%). The results were published in the latest Nature Communications.

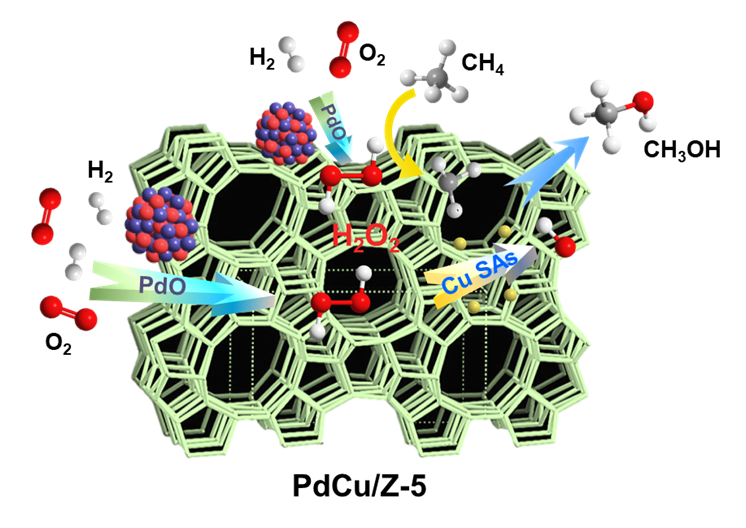

Tandem Catalysis Improve Selective Oxidation of Methane to Oxygenates

a research team led by Prof. SUN Yuhan and Prof. ZHONG Liangshu at Shanghai Advanced Research Institute (SARI) of the Chinese Academy of Sciences reported a ZSM-5 (Z-5) supported PdCu catalyst for selective oxidation of CH4 to oxygenates using O2 in the presence of H2. The as-obtained PdCu/Z-5 catalyst exhibited a high oxygenates yield of 1178 mmol/gPd/h with oxygenates selectivity of 95% at 120 °C. The research results were published in the latest issue of Angew. Chem. Int. Ed.

Researchers Propose Direct Convertion of Methane to Acetic Acid with Ultrahigh Selectivity over Fe Binuclear Sites

Direct conversion of methane to chemicals at mild conditions is regarded as the “Holy Grail” reaction in catalysis science, which has attracted numerous research interests from both industrial and academics. Inspired by these challenges, a research team led by Prof. Yuhan Sun and Prof. Liangshu Zhong at Shanghai Advanced Research Institute (SARI) of the Chinese Academy of Sciences reported the direct conversion of methane to acetic acid (CH3COOH) with ultrahigh selectivity in oxygenated products by direct coupling of CH4, CO and H2O2 over ZSM-5 supported Fe binuclear sites under 30 °C. The research results were published in Chem.

Bifunctional Catalysts Enable High para-Xylene Productivity in Syngas Conversion

Recently, a research group from Shanghai Advanced Research Institute (SARI) of the Chinese Academy of Sciences has fabricated bifunctional catalysts combining versatile zeolites and CoMnAl oxide.These catalysts exhibited high stability and high space-time yield of para-xylene under mild reaction conditions.

New beamlines in trial operation at SSRF

In December 27, four beamlines at the Phase-II project at Shanghai Synchrotron Radiation Facility (SSRF) passed the process test and stared the trail operation, which signified that a total of 11 beamlines and 20 experimental stations have been constructed and put in operation at SSRF.

Researchers Propose a High-loaded Electrocatalyst with High-efficient Performance Expression in PEMFCs

An interdisciplinary research team led by Prof. YANG Hui and Prof. JIANG Zheng of Shanghai Advanced Research Institute reported a high-loaded (44.7 wt.%) and sub-6 nm Pt IMC catalyst, which can be controllable synthesized through a cobalt oxide aided structural-evolution strategy.